🖌️Paintbrush manufacturing is a complex process that requires specialized equipment and machinery to ensure consistent quality and efficient production. As a leading manufacturer of paintbrush machinery, P.G. GROUP S.R.L. has a wealth of experience and expertise in this field. 💪Our state-of-the-art equipment is designed to help business owners achieve better quality products and increase profits.

The first step in the paintbrush manufacturing process is the production of brush filaments. These filaments are made from various materials such as natural hair, synthetic fibers, and bristles. 🌿Our MAP9 automatic printing machine allows for the precise application of identifying marks and brand logos on the filaments, ensuring that your products are easily recognizable and distinguishable from others in the market.

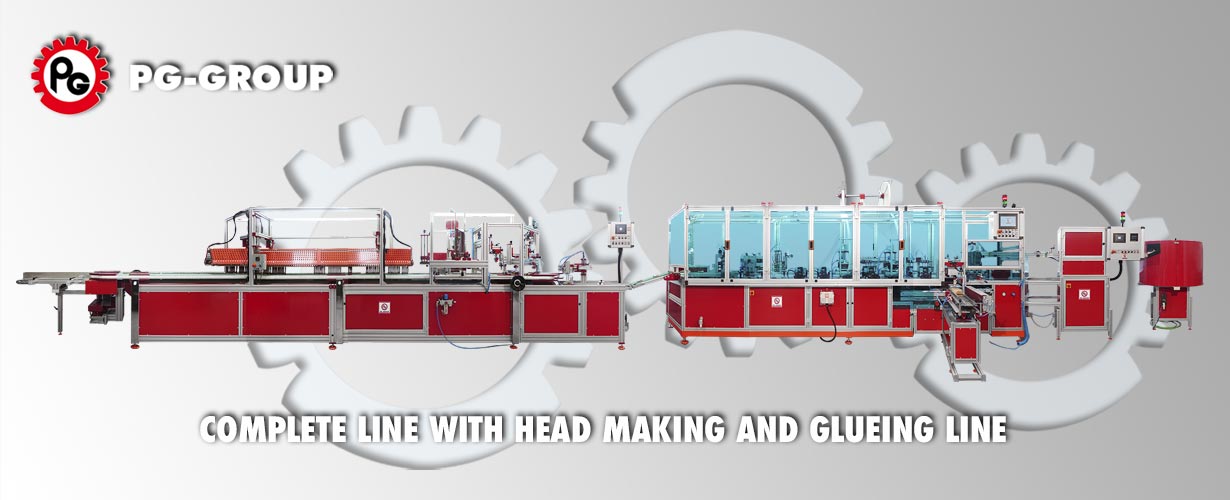

After the filaments have been produced, they are bundled and inserted into ferrules. The ferrules are then attached to the brush handles, which can be made from wood or plastic. 🛠️Our MAP10 automatic assembling machine for brushesallows for the efficient and precise attachment of ferrules to brush handles, while our MAP10-TT automatic head-making machine produces high-quality brush heads with consistent thickness and density.

Once the brush heads have been assembled, they must be cleaned and trimmed to remove any excess materials. 🧼Our MAP3-S automatic paintbrush cleaning machine and MAP4 automatic feed-trimming machine ensure that your brushes are cleaned and trimmed efficiently, saving you time and money.

In addition to our brush manufacturing machinery, P.G. GROUP S.R.L. also offers industrial automation and robotics for maximum efficiency in your production line. 🤖Our MAP1-B universal printing and wrapping machine, MAP1-CT fully automatic walleting machine, and MAP1-D fully automatic packaging machinecan all be integrated into your production line for a streamlined and efficient process.

We also offer modernization, upgrade, and retrofit services for existing paintbrush machinery. This can include the installation of new control systems, motor upgrades, and other improvements that can increase the productivity and efficiency of your existing equipment. 💡

Investing in P.G. GROUP S.R.L. equipment can help paintbrush manufacturers achieve better quality products and increase profits by optimizing the production process. Our state-of-the-art machinery and industrial automation solutions are designed to meet the unique needs of your business and help you stay ahead of the competition. 🚀 Contact us today to learn more about how we can help your business succeed. 💼

📌 Contact Us:

📍 P.G. GROUP SRL

33070 Sarone di Caneva (PN), Italy

📍 Address: Via Col De Rust, 9/A

📞 Phone: 0434-77470

📱 WhatsApp: +39 376 207 7510

🌐 Website: https://thepgg.com/

📧 Email: info@pg-group.it | alex@pg-group.it

💼 Contact us today to discuss your project!

The first step in the paintbrush manufacturing process is the production of brush filaments. These filaments are made from various materials such as natural hair, synthetic fibers, and bristles. 🌿Our MAP9 automatic printing machine allows for the precise application of identifying marks and brand logos on the filaments, ensuring that your products are easily recognizable and distinguishable from others in the market.

After the filaments have been produced, they are bundled and inserted into ferrules. The ferrules are then attached to the brush handles, which can be made from wood or plastic. 🛠️Our MAP10 automatic assembling machine for brushesallows for the efficient and precise attachment of ferrules to brush handles, while our MAP10-TT automatic head-making machine produces high-quality brush heads with consistent thickness and density.

Once the brush heads have been assembled, they must be cleaned and trimmed to remove any excess materials. 🧼Our MAP3-S automatic paintbrush cleaning machine and MAP4 automatic feed-trimming machine ensure that your brushes are cleaned and trimmed efficiently, saving you time and money.

In addition to our brush manufacturing machinery, P.G. GROUP S.R.L. also offers industrial automation and robotics for maximum efficiency in your production line. 🤖Our MAP1-B universal printing and wrapping machine, MAP1-CT fully automatic walleting machine, and MAP1-D fully automatic packaging machinecan all be integrated into your production line for a streamlined and efficient process.

We also offer modernization, upgrade, and retrofit services for existing paintbrush machinery. This can include the installation of new control systems, motor upgrades, and other improvements that can increase the productivity and efficiency of your existing equipment. 💡

Investing in P.G. GROUP S.R.L. equipment can help paintbrush manufacturers achieve better quality products and increase profits by optimizing the production process. Our state-of-the-art machinery and industrial automation solutions are designed to meet the unique needs of your business and help you stay ahead of the competition. 🚀 Contact us today to learn more about how we can help your business succeed. 💼

📌 Contact Us:

📍 P.G. GROUP SRL

33070 Sarone di Caneva (PN), Italy

📍 Address: Via Col De Rust, 9/A

📞 Phone: 0434-77470

📱 WhatsApp: +39 376 207 7510

🌐 Website: https://thepgg.com/

📧 Email: info@pg-group.it | alex@pg-group.it

💼 Contact us today to discuss your project!